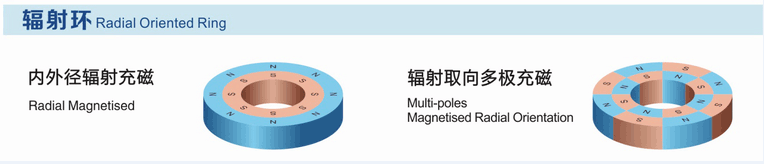

Sinter NdFeB Radial Oriented Ring

- group name

- NdFeb Magnets

- Min Order

- 1 piece

- brand name

- CINFER Magnet

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C

- update time

- Thu, 06 Dec 2018 13:54:22 GMT

Paramtents

Material Sinter NdFeB Radial Oriented Ring

Shape Circular Ring

Coating Ni, Ni-Cu-Ni, Electroless Nickel, Zinc, Colored Zinc, Epoxy

Certificate ISO/TS 16949, ISO9001, ISO14001, RoHS, REACH

Packing Standard sea or air packing, such as carton, wooden box, pallet etc.

Lead time 15 days for samples, 30-45 days for mass production.

Transportation courier (TNT, DHL, FedEx, UPS), air or sea.

Packging & Delivery

-

Min Order1 piece

Briefing

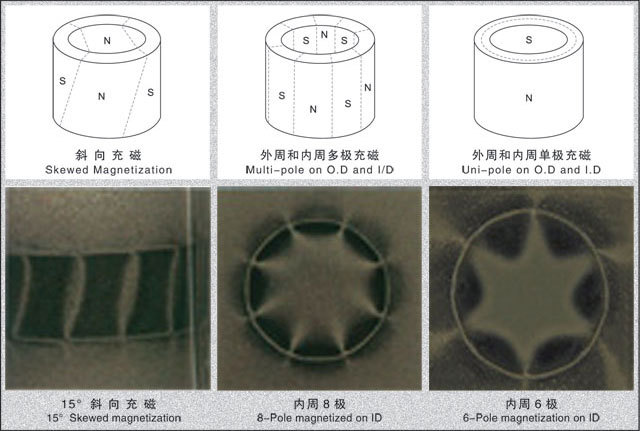

It can be magnetized by 3ways:Uni-pole on O.D and I.D、Multi-pole on O.D and I.D、Skewed Magnetization

Detailed

Radial ring is a whole radial oriented ring magnet.It can be magnetized by 3ways:Uni-pole on O.D and I.D、Multi-pole on O.D and I.D、Skewed Magnetization The ring is mainly used as induction magnet for motors.It imporves motors performance and effciency,and also radial ring is the market trends of motor.

Advantage of Radially oriented sintered NdFeB ring

1.Assenbly easiy,installation of one rings than glusing arcs into place,simple and quick.and good performance of dynamic blance.

2.Be kin to sine wave.

3.Radial sintering assures no "weak spots"

4.Magnets are multi-poled ring does not compromise the magnetic properties.

5.Be straight or skewed magnetized after assembly,provide a possibility of unique design by truly different magnetic circuit.

6.Radial ring direftly determines the shape tolerance,the tolerance of outer and inner diameter can achieve±0.04mm,and has the good coaxiality and verticality.