Bonded magnet of ours can be divided into Compression Molding NdFeB, Injection Molding NdFeB a It is often used to substantially reduce the size of designs that used ceramic magnet materials.

Significant size reductions can be achieved because this kind of material is approximately 3 times stronger than ceramic magnet material. In addition, since the material is isotropic, it can be magnetized multi-polar, such as a N-S-N-S pattern on the outer diameter of a ring. They can be found in a wide variety of applications including office automation equipments, electric fitting devices, miro-driving motors.ect.

Unlike sintered magnet, bonded magnet is a special form of NdFeB powder blended with a plastic carrier material. They are depressed and heated to solid. Parts made in this way can be of complex shapes and come off the tool with tight tolerances. No need for further mechanical machining. Another benefit of the injection molding process is that magnet material can be directly molded into, onto, or against other assembly components eliminating subsequent assembly steps.

The Traits And Applications Of Injection Molding NdFeB Magnet

Traits: Have The Rigidity And Elastic, Can Be Processed Into Thin-Walled Ring, Rods, Slice And Various Special Complex Shapes. Can Make The Magnets And Other Metal Inlays (Gear, Screw, Dysmorphism Hole Etc.) A Time To Shape, It Is Not Easy To Have The Crevasse And Break. Magnets Need Not Cutting And Mechanical Processing, The Product Yield High. After The Formation, The Tolerance Precision Is High. The Surface Is Bright And Clean, The Magnet Internal Uniformity Is Good. The Surface Magnetic Field Uniformity Is Good, The Corrosion Preventing Is Strong.

Applications: Mainly Used For Sensors, Brushless Motors, Automobile Electronic Throttle Pedal, Car Instrument, The Criver, Auto Speed Table, Fuear Instrument Dl Table, Etc.

Bonded Injection Moulding NdFeB Magnetic Property Table

牌号 Grade | 剩 磁 Br Residual Induction | 矫顽力Hcb Coercive Force | 内禀矫顽力Hcj Intrinsic Coercive Force | 磁 能 积 (BH)max Maximum Energy Product | 密度 D Density | 可逆磁导率Recoil Permeability | 剩磁可逆温度系数α Br Irreversible Temperature Coefficient | 最高工作温度Tw Maximum Working Temperature |

Unit | kGs | T | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ | g/cm³ | urec | %/ ℃ | ℃ |

| min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | typ | typ | max |

BNI-3 | 2.0 | 3.0 | 0.20 | 0.30 | 2.0 | 3.0 | 160 | 240 | 6.0 | 8.0 | 480 | 640 | 1.50 | 3.00 | 12 | 24 | 3.9 | 4.4 | 1.2 | -0.11 | 120 |

BNI-4 | 3.5 | 4.5 | 0.35 | 0.45 | 3.0 | 4.0 | 240 | 320 | 7.0 | 9.0 | 560 | 720 | 3.00 | 4.50 | 24 | 36 | 4.2 | 4.9 | 1.2 | -0.11 | 120 |

BNI-5 | 4.5 | 5.2 | 0.45 | 0.52 | 4.0 | 4.5 | 320 | 360 | 7.0 | 9.0 | 560 | 720 | 4.50 | 5.50 | 36 | 44 | 4.5 | 5 | 1.2 | -0.11 | 120 |

BNI-5H(PPS) | 4.8 | 5.2 | 0.48 | 0.52 | 5.0 | 6.0 | 400 | 480 | 11.0 | 13.0 | 880 | 1040 | 4.50 | 5.50 | 36 | 44 | 4.9 | 5.4 | 1.2 | -0.11 | 180 |

BNI-6 | 5.0 | 5.5 | 0.50 | 0.55 | 4.0 | 5.5 | 320 | 440 | 8.0 | 10.0 | 640 | 800 | 5.50 | 6.50 | 44 | 52 | 4.7 | 5.1 | 1.2 | -0.11 | 120 |

BNI-7 | 5.4 | 6.4 | 0.54 | 0.64 | 4.0 | 5.0 | 320 | 400 | 8.0 | 10.0 | 640 | 800 | 6.50 | 7.50 | 52 | 60 | 5 | 5.5 | 1.2 | -0.12 | 120 |

BNI-8 | 6.4 | 7.4 | 0.64 | 0.74 | 5.0 | 6.0 | 400 | 480 | 8.0 | 10.0 | 640 | 800 | 8.50 | 9.50 | 68 | 76 | 5.5 | 5.9 | 1.2 | -0.11 | 120 |

The Traits And Applications Of Compression Molding NdFeB Magnet

Traits: Br, Hcb And (BH)Max Are High, The Cost Performance Is Good. Easy Processing Various Complex Shape, Various Sizes And Small Specifications Of Products; Coating Or The Plating Corrosion Resistance Is Low.

Applications: Mainly Used For Office Automation Equipment, Electrical Machinery, Audio-Visual Equipment, Instrumentation, Small Motor And Measuring Machines, Mobile Phones, CD-ROM、DVD-ROM Drive Motor, Hard Disk Spindle Motor HDD, Other Micro & Special Dc Motor And Automated Instrumentation, Etc.

Bonded Compression Molding NdFeB Magnetic Property Table

牌号 Grade | 剩 磁 Br Residual Induction | 矫顽力 Hcb Coercive Force | 内禀矫顽力 Hcj Intrinsic Coercive Force | 最大磁能积(BH) max Maximum Energy Product | 密度D Density | 可逆磁导率Recoil Permeability | 剩磁可逆温度系 数 α Br Temperature Coefficient | 居里温度 Tc Curie Temerature | 工作温度 Tw Max.Operating Temperature |

Unit | T | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | g/cm³ | μrec | %/ ℃ | ℃ | ℃ |

| min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | min | max | typ | typ | typ | max |

BNC-2 | 0.3 | 0.4 | 3.0 | 4.0 | 160 | 240 | 2.0 | 3.0 | 480 | 640 | 6.0 | 8.0 | 16 | 24 | 2.0 | 3.0 | 4.5 | 6.0 | 1.2 | -0.11 | 300 | 160 |

BNC-4 | 0.4 | 0.5 | 4.0 | 5.0 | 240 | 320 | 3.0 | 4.0 | 560 | 720 | 7.0 | 9.0 | 32 | 44 | 4.0 | 5.5 | 5.2 | 6.0 | 1.2 | -0.11 | 300 | 160 |

BNC-6 | 0.5 | 0.6 | 5.0 | 6.0 | 320 | 400 | 4.0 | 5.0 | 480 | 640 | 6.0 | 8.0 | 48 | 60 | 6.0 | 7.5 | 5.5 | 6.0 | 1.2 | -0.11 | 300 | 160 |

BNC-8 | 0.6 | 0.68 | 6.0 | 6.8 | 360 | 440 | 4.5 | 5.5 | 640 | 800 | 8.0 | 10.0 | 64 | 72 | 8.0 | 9.0 | 5.8 | 6.1 | 1.2 | -0.11 | 300 | 160 |

BNC-8H | 0.6 | 0.65 | 6.0 | 6.5 | 400 | 480 | 5.0 | 6.0 | 1120 | 1280 | 14.0 | 16.0 | 60 | 68 | 7.5 | 8.5 | 5.8 | 6.2 | 1.2 | -0.1 | 350 | 180 |

BNC-8L | 0.6 | 0.68 | 6.0 | 6.8 | 400 | 480 | 5.0 | 6.0 | 900 | 1120 | 11.3 | 14.0 | 64 | 72 | 8.0 | 9.0 | 5.8 | 6.2 | 1.2 | -0.1 | 350 | 160 |

BNC-9 | 0.6 | 0.68 | 6.0 | 6.8 | 400 | 480 | 5.0 | 6.0 | 640 | 800 | 8.0 | 10.0 | 68 | 72 | 8.5 | 9.0 | 5.8 | 6.2 | 1.2 | -0.1 | 350 | 160 |

BNC-10 | 0.68 | 0.73 | 6.8 | 7.3 | 400 | 480 | 5.0 | 6.0 | 640 | 800 | 8.0 | 10.0 | 76 | 84 | 9.5 | 10.5 | 5.8 | 6.2 | 1.2 | -0.1 | 350 | 160 |

BNC-12 | 0.71 | 0.75 | 7.1 | 7.5 | 440 | 520 | 5.5 | 6.5 | 720 | 800 | 9.0 | 10.0 | 84 | 96 | 10.5 | 12.0 | 6.0 | 6.2 | 1.2 | -0.1 | 350 | 160 |

BNC-12L | 0.72 | 0.76 | 7.2 | 7.6 | 400 | 480 | 5.0 | 6.0 | 480 | 640 | 6.0 | 8.0 | 84 | 96 | 10.5 | 12.0 | 6.0 | 6.2 | 1.2 | -0.12 | 320 | 160 |

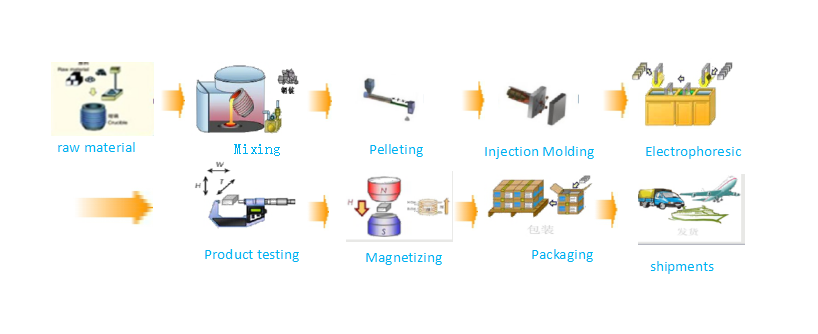

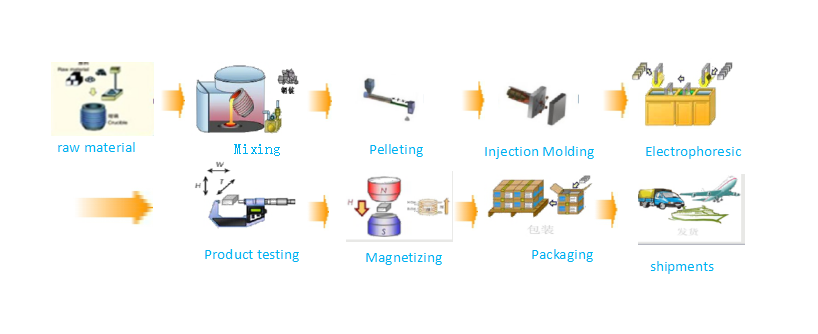

Injection Molding NdFeB Magnet Manufacturing process

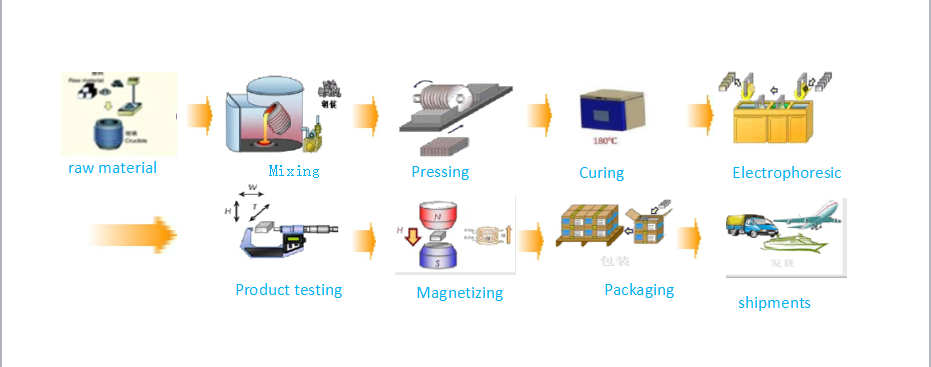

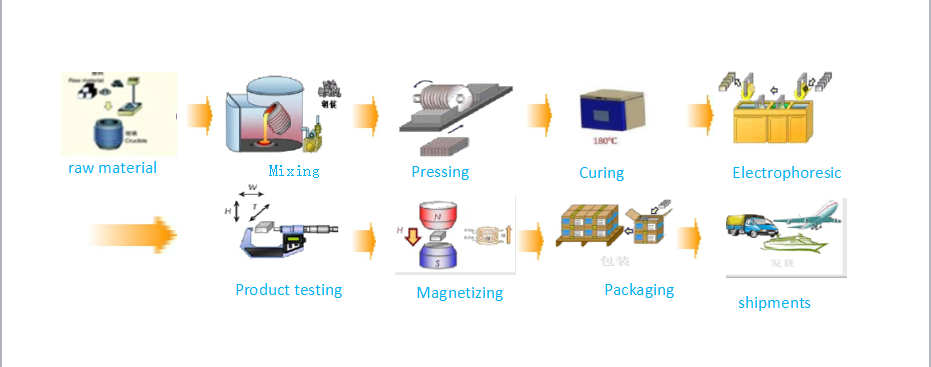

Compression Molding NdFeB Magnet Manufacturing process